* DYE or PIGMENT COLORANT

* ADDITIVES

Ink is a primary tool used to convey a message and give decoration to a substrate. For this to occur an ink must have specific properties if it is to perform properly. It is of no value if it will not transfer to the substrate or adhere in a proper manor. Ink makers must cater for a wide variety of requirements and retain the ability to be flexible in what they manufacture. The contents of any ink are dependent on the conditions under which the products are to be printed and the end use requirements of the printed piece. At its basic definition ink is a combination of components mixed together to form a fluid capable of printing from a printing device.

DYE COLORANT

Dyes are the coloring material that color commodities of our day to day use. Hardly there is any industry where dyes are not used commercially. From plastic toys for children to that jazzy t-shirt of yours, every where there is application of dyes.

Dye colorants are easily produced and is used in approximately half of the consumer inkjet printers in the world today. Dyes can be said to be colored, ionizing and aromatic organic compounds which shows an affinity towards the substrate to which it is being applied. It is generally applied in a solution that is aqueous. Dyes may also require a mordant to better the fastness of the dye on the material on which it is applied.

Dyes are the largest group that can easily be manipulate to our liking. Dyes are applied to numerous substrates, for example to textiles, leather, plastic, paper etc. in liquid form. One characteristic of dye is that the dyes must get completely or at least partially soluble in which it is being put to. The rule that we apply to other chemicals is similarly applicable to dyes also.

There are several ways for classification of dyes. It should be noted that each class of dye has a very unique chemistry, structure and particular way of bonding. While some dyes can react chemically with the substrates forming strong bonds in the process, others can be held by physical forces. Some of the prominent ways of classification is given hereunder.

There are several ways for classification of dyes. It should be noted that each class of dye has a very unique chemistry, structure and particular way of bonding. While some dyes can react chemically with the substrates forming strong bonds in the process, others can be held by physical forces. Some of the prominent ways of classification is given hereunder.

- Organic/Inorganic

- Natural/Synthetic

- By area and method of application

- Chemical classification- Based on the nature of their respective chromophores.

By nature of the Electronic Excitation (i.e, energy transfer colorants, absorption colorants and fluorescent colorants).

According to the dyeing methods

- Anionic (for Protein fiber)

- Direct (Cellulose)

- Disperse (Polyamide fibers)

However the most popular classification is the one that is advocated by the US International Trade Commission (classifies dyes into 12 types).

PIGMENT COLORANT

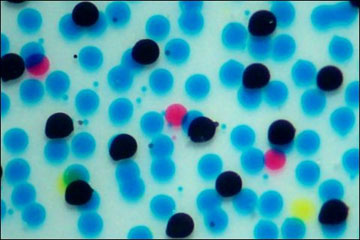

Pigments are generally colored, organic or inorganic solid powder, and usually are insoluble. They are not affected physically or chemically in the substrate in which they are incorporated. Pigments can give a full range of colors. Pigments have a variety of applications that includes plastics, ink, and coating applications.

Pigment colorants are more difficult to produce and are used in the other half of the consumer inkjet printers, along with most business inkjet printers and select large format, page-wide and wide-format inkjet printing devices. Pigment inks provide archivability (i.e. image longevity or lightfastness) which helps prevent prints from fading prematurely due to higher levels of light exposure. It is common for most black inks to have pigment properties as this provide higher dot gain and allows customers to more easily read black printed text on paper (due to higher dot gain). Pigment is also the major cost in an ink far exceeding all other components.

The pigments are versatile coloring agents that comes with all round features to give credence to its suitability in a variety of mediums. Some of the striking features are given here:

- Excellent light and weather fastness

- A good baking stability that makes them suitable for automotive and other industrial paints

- High tinting strength

- Good over spray fastness when applied in paints

- Gives heat stability of around 300° C in the case of Polyolefins Plastics

- Excellent solvent resistance properties

- Easily dispersible

- Consistency and uniqueness of shades

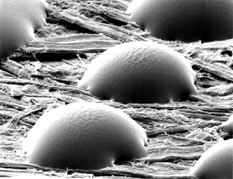

Pigments give color to a substrate by either remaining on the surface or having a tendency to fill in voids on the substrate. An example would be a coated sheet versus an uncoated sheet where the ink will remain on the surface of the coated sheet and fill the voids of an uncoated sheet. Colorant/Pigment is provided to the ink manufacturer in two forms, a dry powder, or in a paste form where the pigment has been wetted with another agent. Most are synthetic materials produced from petroleum chemicals, which are inorganic, while others are organic and formed by nature in mineral or vegetable form.

ADDITIVES

A major component of ink are additives. Additives are very specialized components that give ink special properties that dye or pigment will not do by themselves. The addition of additives is what really specializes an ink all to its own. There are many types of additives that an ink manufacturer has at its disposal. Many of them are used in such small percentages, on a per batch bases, that it would surprise you. Example, typically only 2% to 3%, by weight, of drying agents are mixed into a batch of ink.

One group of additives is oils and solvents. This group is used for flow and lubrication properties and can also influence drying characteristics – these are common in high end commercial printing devices used for outdoor applications (i.e. banners and signs printed using solvent-based inks which can withstand the elements of a fierce winter storm). Various types of oils are linseed oil, which is obtained from the seeds of flax and tung oil, also known as china wood oil, is obtained from the seed of a nut. Mineral oils, or solvents, are petroleum-based products. In the last couple of years there has been a practice of using less mineral oils/solvents due to EPA and Government regulations concerning V.O.C.’s (volatile organic compounds). Many manufacturers have found substitutes to replace petroleum-based products with those that are obtained from plant matter such as tung and linseed.

We also use special waxes to impart mar-resistance, improve slip, rub and scuff properties of ink. Most waxes are used for hard dry applications to give ink toughness and durability. Waxes can be used in two forms, a dry form that is very small in particle size or in a wet form where the wax has already been dispersed into a varnish.

A very important component of ink is its drying mechanism. Driers are used as a catalyst to promote oxidation. In the presence of driers, oxidation proceeds rapidly and the ink films dry hard in shorter periods of time. Cobalt and manganese are the two most common. Driers come in two forms, as a liquid drier or a paste drier.

Some other special additives are antioxidants, which gives an ink a stay fresh property, or a non-skinning characteristic. Soy or vegetable compounds are used to replace petroleum products as an environmental concern. We also use agents so ink will “bite” in certain types of substrates, usually a hard surface or synthetic substrate. Ph buffers are used to give balance and control between ink and fountain solution. Combinations of these components is what gives ink all of its properties and characteristics, which is basically to turn a liquid to a solid.

* VISUAL

* GIVEN PROCESS

* DRY

* ADHERE

* RESISTANCE

AN INK IS TO GIVE VISUAL CHARACTER

We can formulate ink, in varying degrees, with the use of the before mentioned components.

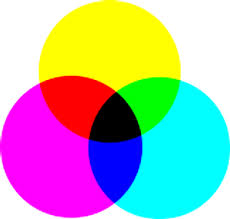

As a basic rule ink is formulated to give 5 characteristics in order to perform. First, ink is to give visual character to a printed surface. Visual character can be broken down into three properties:

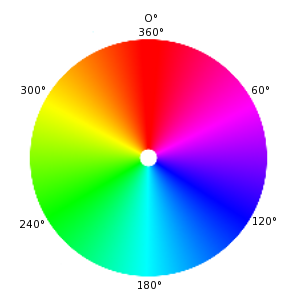

- Hue – indicates what color the ink is.

- Strength – is a measure of the color’s intensity or saturation.

- Purity – indicates how bright or dark a color is.

Types of pigments, varnishes, oils and solvents all can alter the inks hue, strength and purity.

Ink vehicle (i.e. cohesion medium) can also affect ink. It must be capable of keeping the pigment dispersed or you may have loss of strength or a vehicle that penetrates the substrate too much will lower strength.

PRINT BY A GIVEN PROCESS

From a high-level industry vantage point the formulation of ink is greatly determined by the method of printing being used. Various types of printing, such as inkjet, solvent, flexography, gravure, screen, UV, sheet fed or web inks all influence how the ink will be manufactured. Each process is most significant to the formulation of the ink.

COMMERCIAL PRINTING – DRY UNDER SPECIFIC CONDITIONS

* ABSORPTION

* OXIDATION

* EVAPORATION

* RADIATION

In commercial printing applications, inks are designed to dry by various means. The drying mechanism is dictated by the printing process being used and by the substrate being printed. Absorption is when ink penetrates the fibers of a substrate and is absorbed into the substrate. The degree of penetration determines the ‘dry’ ability of ink. Oxidation is when the oxygen in the atmosphere chemically combines with the varnish system converting it from a liquid to a solid. A catalyst is used, a drier, to promote the oxidation of the drying oils. Oxidation rapidly proceeds and ink films dry hard in shorter periods of time. Evaporation is when a solvent is physically removed from the ink leaving it to bind to the substrate. Heat set web is the best example of evaporation. Radiation cure is with the use of ultraviolet, or UV, drying. Special UV inks must be used for this type of drying. In most cases the printing press has some form of heat to speed the drying and setting process of the inks. Examples are IR driers, hot air knives and other forms of mechanical heat generated at or near the delivery of the press.

the substrate being printed. Absorption is when ink penetrates the fibers of a substrate and is absorbed into the substrate. The degree of penetration determines the ‘dry’ ability of ink. Oxidation is when the oxygen in the atmosphere chemically combines with the varnish system converting it from a liquid to a solid. A catalyst is used, a drier, to promote the oxidation of the drying oils. Oxidation rapidly proceeds and ink films dry hard in shorter periods of time. Evaporation is when a solvent is physically removed from the ink leaving it to bind to the substrate. Heat set web is the best example of evaporation. Radiation cure is with the use of ultraviolet, or UV, drying. Special UV inks must be used for this type of drying. In most cases the printing press has some form of heat to speed the drying and setting process of the inks. Examples are IR driers, hot air knives and other forms of mechanical heat generated at or near the delivery of the press.

It is the ink manufacturers task to produce a carefully balanced formulation to ensure a high quality product…this is particularly important for high-speed printing presses, and still maintain the drying process at a satisfactory rate. There is a very thin line with the additions of driers. Not enough drier will naturally slow down the setting process, but too much drier will have the press operator pulling rollers from his/her press. Also when adding driers, too high of a percentage of drier will actually de-activate itself and never fully cure.

ADHERE TO A GIVEN MATERIAL

Ink is to adhere and bind the color to the substrate and keep it there. Pigments have little or no effect concerning adhesion. For wide-format (LF – large format) printers which leverage solvent or eco-solvent inks, the adhesive nature of ink comes from the addition of solvent-based additives, ranging from 2% to as high as 15% of total ink volume. These types of printing systems can print on uncoated materials such as low cost rolls of vinyl and the ink will ‘stick’.

For some very high-end digital printing systems, the addition of varnish is needed. Choice of varnish for specific substrates is very important. Naturally you will need different varnishes for synthetic substrates as compared to a regular coated or uncoated substrate. Adhesion to various substrates uncoated, coated, matte, vinyl, acetate, foil or other synthetic substrates must be taken into account when formulating ink.

HAVE SPECIAL RESISTANCE PROPERTIES

Inks must be able to resist certain types of chemical or physical attack. First, the ink must withstand the manufacturing process used to make it, the grinding and rolling on an ink mill, the shear of an ink mixer and the heat generated in the process. They must be able to withstand the rigors of the printing process itself. Conditions of high shear and heat generated on press as well as the addition of fountain solutions and alcohol.

Once printed, ink must be able to withstand finishing processes as cutting, folding, gluing, foil stamping, die cutting, coating or any bindery work. It also must withstand the severity of transportation. As a finished product it must withstand the rigors of the end use. Package for a product, a book, a pocket folder, a calendar etc. Since you are converting a liquid to a solid it must be able to bind, adhere, have rub and scuff resistance, heat resistance and elasticity to withstand all of these situations.

Ink Safety

Water-Based Dye and Pigmented Inks (including Latex) are inherently the safest of all the inks available today. For more information refer to Sign & Digital Graphics article.

Bottom line, while not all inks are ‘mountain grown’ like some coffees claim, manufacturing inks is a complicated process depending on the print purpose or type of application.

————

Refilled Ink Cartridges

Refilled cartridges will typically provide every spectrum of the printer’s color rainbow & are essentially on-par with original manufacturer’s ink quality and performance. Our refilled inks are fully compatible with HP, Canon, Epson & Brother printers. With a streamlined operator-assisted ink refill process, we provide OEM quality at bargain-basement costs. To find an ink cartridge refill store location please choose from the links below.

—

Find an Ink Cartridge Refill Store Near You (USA, Canada, France & Germany)

Premium ink refilling services are provided by major retailers in the USA, Canada, France & Germany. To find the nearest refill store and ink pricing, refer to links below:

Auchan, E.LeClerc, Cora & Intermarche France

Worldwide Ink Refill Store Locator

Retail Inkjet Solutions (Ink Refill Equipment Provider)

—–

For questions regarding refilled cartridge usage, printer questions/problems, new cartridge support offerings or ink refill locations please Contact Us.